Your Go-To Experts for Commercial & Industrial Pumps in Jacksonville, FL

Pumps are the unsung heroes of almost every facility: circulating cooling water in the HVAC systems, providing feed water to the boilers and the boilers' deaerators, moving process fluids across the manufacturing floor, augmenting city or commercial building water pressure and so on.

Yet, pumps, so greatly needed in any industry, generally do not get a second thought until performances plummet, energy consumption soars, or an unforeseen failure causes a production standstill. And that's when a proactive pump-service partner with technical prowess steps in.

At Boiler Technologies Unlimited, we know how inline pumps, base-mounted pumps, axially split case pumps, and a myriad of specialized equipment are essential to keep businesses in Jacksonville running.

Our decades of combined experience—with training and certification from manufacturers and their vendors—will be geared towards the optimization of your pump installations through adequate maintenance to enhance the service life of equipment and provide rapid and reliable repairs for restoring system uptime.

Our Commercial and Industrial Pump Services in Jacksonville

Inline Pumps

Inline pumps serve the purpose well wherever the area is confined and has straight-through piping, like mostly found in mechanical closets and narrow utility rooms. We assist you in picking the right size and configuration for your flow requirements, pump head, and characteristics of fluid, such as temperature, viscosity, and solids content. Our service technicians carry out full dynamic balancing, check the mechanical seal, inspect the alignment, and do vibration measurements to maintain affordable vibration levels. Proper commissioning and continued maintenance will permit inline pumps to run quietly and reliably within HVAC loops, chilled-water, and domestic-hot-water recirculation systems.

Base-Mounted Pumps

Base-mounted pumps sit on a skid or a foundation and are typically installed with larger motors or gear reducers for more major applications. We design rigid, vibration-damped bases and align shafts to industry-tight tolerances so that early bearing, coupling, and seal failures do not occur. During maintenance visits, pump bearings are checked, wear rings replaced, and conditions caused by thermal growth studied on hot-water or steam-service pumps. Base-mounted pumps handle everything else—from glycol mixtures in district-cooling plants to boiler-feedwater in industrial operations-our expertise in this area guarantees performance to meet desired service levels over the years.

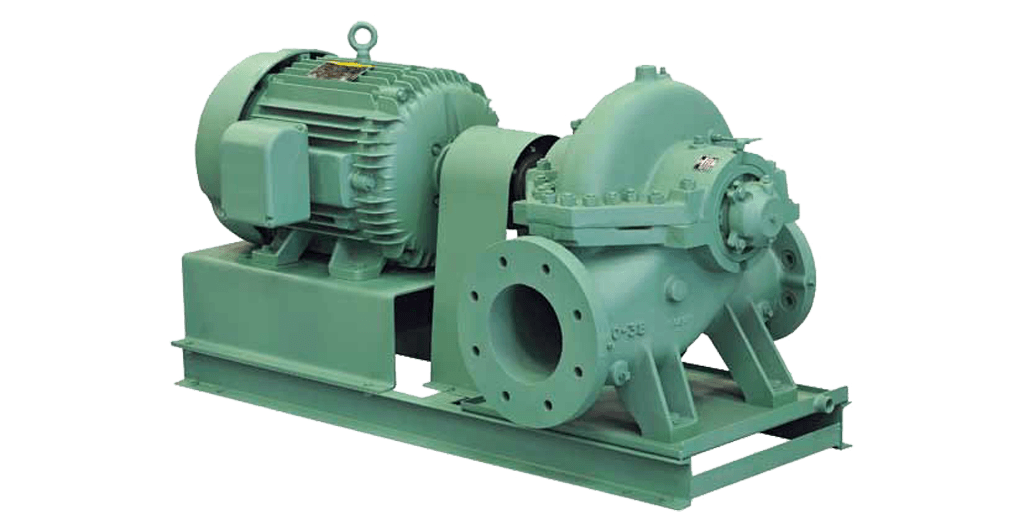

Axially Split Case Pumps

For high-flow, high-pressure applications such as cooling tower make-up water, large-scale irrigation, or industrial water circulation, axially split case pumps are the answer. Since it's divided into two cases, the impeller and wear components can be accessed without disturbing pipe connections. Our crews carry out trim optimizations, clear lodged debris, and rebalance impellers to reduce vibration and prolong seal life. In addition, complete overhauls are performed, which include machining pump casings that are no longer within specification, replacing stuffing boxes or mechanical seals, and realigning the entire assembly to exact specifications.

Water Pump Installation

An excellent water pump installation goes beyond just bolting the unit to the floor. Our experts perform complete system assessments—mapping flow paths, calculating head losses, and recommending pipe-sizes and valve locations. Foundation grouting can be carried out to avoid movement; piping supports can eliminate undue stress on pump flanges; and assembly commissioning can be done with dynamic balancing and vibration analysis to carry out reliable operation. You will receive as-built documentation and operator training upon operation so that it can be used safely and effectively.

Water Pump Maintenance

Your pump systems, like a car, must receive regular maintenance to avoid unexpected downtime. Preventive maintenance will include, but is not limited to, bearing lubrication; seal-replacement cycles; alignment checks; and performance-curve verification. Trace lifetime wear components, such as impellers, shafts, and bearings, will be used to suggest proactive part swaps before failures occur. With the maintenance intervals tailored to your pump's duty cycle and fluid properties, emergency repairs can be avoided.

Industrial & Commercial Water Pumps

We dimensioned equipment to your precise specifications, whether it involves

industrial water pumps that transfer process liquids for cooling towers or commercial water pumps used in office buildings and retail complexes. We take into account factors like NPSH (net positive suction head), changes in flow rates, and the properties of the fluid, such as pH, particle content, and thickness, to choose the right pump models and materials that will work well in the coastal, humid environment of Jacksonville.

Slide title

Write your caption hereButton

Benefits of Professional Pump Services

According to experts, investing in pump services lends itself to operational and financial benefits.

Energy Efficiency & Saving Cost

A pump of an appropriate size and tuning consumes less power. Energy use can be reduced up to 70% via integration of the VFDs or ECM technology under part-load conditions, which means substantial savings in the utility bills vis-a-vis the life of the equipment.

Downtime Reduction & Reliability Increase

Scheduled maintenance goes towards preventing breakdowns that are not forecasted. Lesser chances of emergency repairs taking place with our preventive maintenance plans; however, should one occur, our rapid response team will quickly have your pumps online once again.

Extended Equipment Lifespan

Catering to small issues—damaged bearings, misalignment, or seal leakages at a premature stage—prevents a capital input from his early demolishment. Pumps that undergo maintenance practices will always exceed their expected lifespan.

Why Choose Boiler Technologies Unlimited for Commercial and Industrial Pump Services in Jacksonville

Community-Focused Expertise

Judging by our years of experience here in Jacksonville, our team knows the local water chemistry, climate stresses, and code requirements, which allows for pump selections and maintenance intervals tailored toward your area.

Decades of Technical Experience

The technicians are factory-certified by the major pump manufacturers. They regularly undergo continuing education and field training to keep abreast of the latest pump technology and techniques. Whatever the challenge with a pump, we approach it with standard best practices and the latest diagnostic tools.

Transparent, Customer-First Communication

You receive estimates in clear language, easily understood scope-of-work documents, and detailed reports on the work performed. No hidden charges apply, and our recommendations are communicated clearly to empower you.

Emergency Response Service

Pump failure can disrupt entire systems. That is why our service fleet, located in Jacksonville, is ready 24/7 to leap into action in case of an emergency, reducing potential downtime and safeguarding your profits.

Finding “Water Pump Services Near Me” in Jacksonville

Jacksonville's companies depend on dependable water pump systems, so we are here to ensure yours runs at best. Our staff is available to help with a new installation, emergency repairs, preventative maintenance schedule or otherwise.

To arrange a consultation and learn how our

commercial and industrial pump services in Jacksonville might improve your business, get in touch Boiler Technologies Unlimited now.

Let us handle your pump system so you can concentrate on confidently running your company.

Frequently Asked Questions

How often should I schedule maintenance for my commercial or industrial pumps?

The number of maintenance tasks to be carried out depends on a duty cycle of pump operation, properties of fluids, and pump criticality. As a rule of thumb, general-purpose HVAC or water-transfer pumps benefited from a check every three months, while process-critical pumps with abrasive or corrosive fluids may need a close inspection every month.

What are the warning signs of a failing pump?

Key signs are increased vibration or noise, operational problems with flow or pressure drop, increased power consumption, leakage from the seals, and sudden bearing temperatures. Early detection through vibration or thermal imaging can secure against complete failure.

Can variable-speed drives be retrofitted to my existing pumps?

Definitely. VFD retrofits are one of the most economical solutions to improve energy efficiency and process control. We assess the compatibility of your motors, recommend drives sized according to your load profile, and carry out all programming and commissioning.

How do you determine the right pump material for my application?

We will analyze the chemistry, temperature, solids content, and flow characteristics of the fluid. For corrosive or abrasive fluids, stainless steel or duplex alloys would probably be specified, along with hard-coated impellers. For clean, potable water, cast iron or bronze would be adequate.

What's included in a pump overhaul?

A full overhaul includes disassembly, cleaning, dimension inspection of the shaft and casing, machining of the worn surface, replacement of the bearings and seals, dynamic balancing of the rotors, and reassembly with precision alignment. Finally, the pump is tested on a certified test stand to confirm its performance prior to reinstallation.

Get Connected for Superior Hospitality Heating Solutions

Now, upgrade your guest experience in the hotel, make reliable operations at resorts, or just give that country club a classy touch with our latest boiler systems and water heaters. New installations or upgrades for existing systems are solutions designed for the hospitality industry water heating. Whenever you require tailor-made heating solutions, contact Boiler Technologies Unlimited.

You can send us your requirements at the email address of matt@boilertechnologies.com

or call us at (866)-288-2677. We are here to assist you with efficient, dependable, and unparalleled hot water solutions for hospitality that are really one in a million.